-

Inviscid Bump in a Channel

Inviscid Supersonic Wedge

Inviscid ONERA M6

Laminar Flat Plate

Laminar Cylinder

Turbulent Flat Plate

Transitional Flat Plate

Transitional Flat Plate for T3A and T3A-

Turbulent ONERA M6

Unsteady NACA0012

Epistemic Uncertainty Quantification of RANS predictions of NACA 0012 airfoil

Non-ideal compressible flow in a supersonic nozzle

Non-ideal compressible flows with physics-informed neural networks

Aachen turbine stage with Mixing-plane

-

Inviscid Hydrofoil

Laminar Flat Plate with Heat Transfer

Turbulent Flat Plate

Turbulent NACA 0012

Laminar Backward-facing Step

Laminar Buoyancy-driven Cavity

Streamwise Periodic Flow

Species Transport

Composition-Dependent model for Species Transport equations

Unsteady von Karman vortex shedding

Turbulent Bend with wall functions

Wind velocity and pollutant dispersion in a city

-

Static Fluid-Structure Interaction (FSI)

Dynamic Fluid-Structure Interaction (FSI) using the Python wrapper and a Nastran structural model

Static Conjugate Heat Transfer (CHT)

Unsteady Conjugate Heat Transfer

Solid-to-Solid Conjugate Heat Transfer with Contact Resistance

Incompressible, Laminar Combustion Simulation

User Defined combustion model with Python

-

Unconstrained shape design of a transonic inviscid airfoil at a cte. AoA

Constrained shape design of a transonic turbulent airfoil at a cte. CL

Constrained shape design of a transonic inviscid wing at a cte. CL

Shape Design With Multiple Objectives and Penalty Functions

Unsteady Shape Optimization NACA0012

Unconstrained shape design of a two way mixing channel

Adjoint design optimization of a turbulent 3D pipe bend

Inviscid Supersonic Wedge

| Written by | for Version | Revised by | Revision date | Revised version |

|---|---|---|---|---|

| @economon | 7.0.0 | @talbring | 2020-03-03 | 7.0.2 |

Solver: |

|

Uses: |

|

Prerequisites: |

None |

Complexity: |

Basic |

Goals

Upon completing this tutorial, the user will be familiar with performing a simulation of supersonic, inviscid flow over a 2D geometry. The specific geometry chosen for the tutorial is a simple wedge in a channel. Consequently, the following capabilities of SU2 will be showcased in this tutorial:

- Steady, 2D Euler equations

- Multigrid

- HLLC convective scheme in space (2nd-order, upwind)

- Euler implicit time integration

- Supersonic Inlet, Outlet, and Euler Wall boundary conditions

The intent of this tutorial is to introduce a simple, inviscid flow problem that will allow users to become familiar with using a CGNS mesh. This will require SU2 to be built with CGNS support (CGNS will be automatically built and linked for you during compilation), and some new options in the configuration file related to CGNS meshes and their conversion will be discussed.

Resources

The resources for this tutorial can be found in the compressible_flow/Inviscid_Wedge directory in the tutorial repository. You will need the configuration file (inv_wedge_HLLC.cfg) and the mesh file (mesh_wedge_inv.cgns).

Tutorial

The following tutorial will walk you through the steps required when solving for the supersonic flow past the wedge using SU2. It is assumed you have already obtained and compiled SU2_CFD with CGNS support. If you have yet to complete these requirements, please see the Download and Installation pages.

Background

This example uses a 2D geometry which features a wedge along the solid lower wall. In supersonic flow, this wedge will create an oblique shock, and its properties can be predicted from the oblique-shock relations for a perfect gas (see your favorite compressible fluids textbook for more information). This is a common test case for CFD codes due to its simplicity along with the ability to verify the code against the oblique-shock relations.

Problem Setup

This problem will solve for the flow over the wedge with these conditions:

- Freestream Pressure = 100000 Pa

- Freestream Temperature = 300 K

- Freestream Mach number = 2.0

- Angle of attack (AOA) = 0.0 deg

Mesh Description

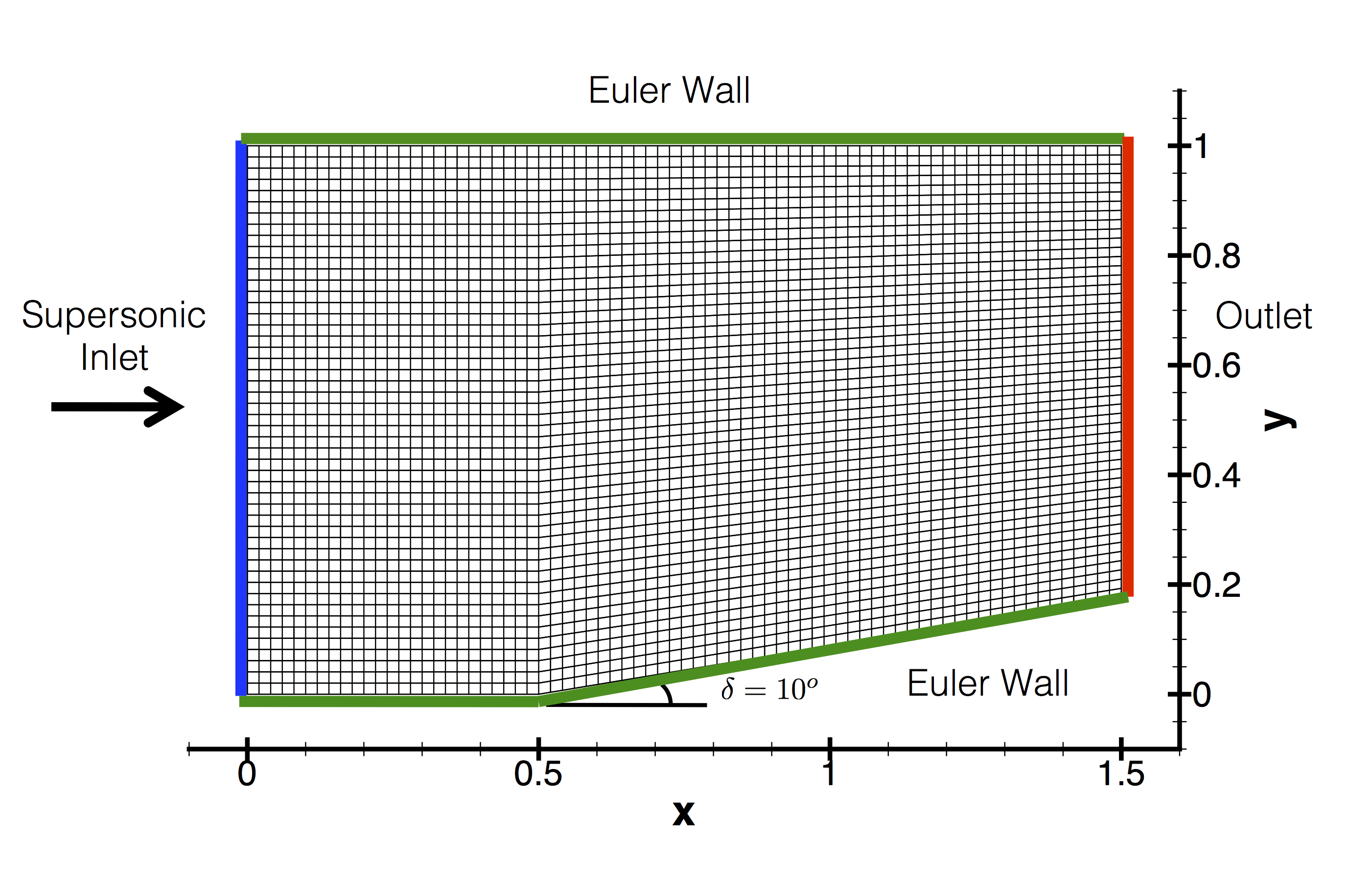

The wedge mesh is a structured mesh (75x50) of rectangular elements with a total of 3,750 nodes. The upper and lower wall of the geometry are solid (MARKER_EULER), and the lower wall has a 10 degree wedge starting at x = 0.5. Figure (1) shows the mesh with the boundary markers and flow conditions highlighted.

Figure (1): The computational mesh with boundary conditions highlighted.

Figure (1): The computational mesh with boundary conditions highlighted.

For this test case, the inlet marker will be set to a MARKER_SUPERSONIC_INLET boundary condition, while the outlet marker will be set to the MARKER_OUTLET condition. In supersonic flow, all characteristics are incoming to the domain at the entrance (inlet marker), and therefore, all flow quantities can be specified, i.e., no information travels upstream.

At the exit, however, all characteristics are outgoing, meaning that no information about the exit conditions is required. Therefore, the outlet marker is set to the outlet boundary condition which, in supersonic flow, simply extrapolates the flow variables from the interior domain to the exit. In practice, a low back pressure is supplied to the MARKER_OUTLET boundary condition in the configuration file, but the propagation of information in this supersonic flow make it unnecessary information.

Configuration File Options

Several of the key configuration file options for working with CGNS meshes are given here. The latest version of SU2 ships with the source code for the CGNS library, and it will automatically be built and linked during the SU2 compilation process. Here, we will discuss a few options in the wedge configuration file as a practical example for getting your own CGNS mesh files working:

% ------------------------- INPUT/OUTPUT INFORMATION --------------------------%

%

% Mesh input file

MESH_FILENAME= mesh_wedge_inv.cgns

%

% Mesh input file format (SU2, CGNS)

MESH_FORMAT= CGNS

To use the supplied CGNS mesh, simply enter the filename and make sure that the MESH_FORMAT option is set to CGNS. The output written to the console during the grid reading process during runtime might look like the following for the supersonic wedge mesh:

------------------- Geometry Preprocessing ( Zone 0 ) -------------------

Reading the CGNS file: mesh_wedge_inv.cgns.

CGNS file contains 1 database(s).

Database 1, Base: cell dimension of 2, physical dimension of 3.

1 total zone(s).

Zone 1, dom-1: 3750 total vertices, 3626 total elements.

Loading CoordinateX values into linear partitions.

Loading CoordinateY values into linear partitions.

Distributing connectivity across all ranks.

Number of connectivity sections is 5.

Section QuadElements contains 3626 elements of type Quadrilateral.

Section inlet contains 49 elements of type Line.

Section lower contains 74 elements of type Line.

Section outlet contains 49 elements of type Line.

Section upper contains 74 elements of type Line.

Loading volume section QuadElements from file.

Loading surface section inlet from file.

Loading surface section lower from file.

Loading surface section outlet from file.

Loading surface section upper from file.

Two dimensional problem.

3750 grid points before partitioning.

3626 volume elements before partitioning.

4 surface markers.

49 boundary elements in index 0 (Marker = inlet).

74 boundary elements in index 1 (Marker = lower).

49 boundary elements in index 2 (Marker = outlet).

74 boundary elements in index 3 (Marker = upper).

SU2 prints out information about the CGNS mesh including the filename, the number of points, and the number of elements. Another useful piece of information is the listing of the sections within the mesh. These descriptions give the type of elements for the section as well as any name given to it. For instance, when the inlet boundary information is read, SU2 prints “Section inlet contains 49 elements of type Line” to the console. This information can be used to verify that your mesh is being read correctly, or to help you remember (or even to learn for the first time) the names for each of the boundary markers that you will need for specifying boundary conditions in the config file.

A converter for creating native .su2 meshes from CGNS meshes is built directly into SU2_DEF, along with many other facilities for manipulating and deforming grids (e.g., scaling, translating, rotating). We will discuss many more capabilities of SU2_DEF in future tutorials, especially features needed for design parameterization and mesh deformation for optimal shape design. To perform a simple conversion of the grid with SU2_DEF, choose the following option:

% ----------------------- DESIGN VARIABLE PARAMETERS --------------------------%

%

% Kind of deformation (NO_DEFORMATION, SCALE_GRID, TRANSLATE_GRID, ROTATE_GRID,

% FFD_SETTING, FFD_NACELLE,

% FFD_CONTROL_POINT, FFD_CAMBER, FFD_THICKNESS, FFD_TWIST

% FFD_CONTROL_POINT_2D, FFD_CAMBER_2D, FFD_THICKNESS_2D,

% FFD_TWIST_2D, HICKS_HENNE, SURFACE_BUMP, SURFACE_FILE)

DV_KIND= NO_DEFORMATION

Provide a name for the converted mesh to be written (set to “mesh_out.su2” by default):

% Mesh output file

MESH_OUT_FILENAME= mesh_out.su2

and lastly, run the SU2_DEF module:

$ SU2_DEF inv_Wedge_HLLC.cfg

No other options related to the grid deformation capability are required. You will now have a new mesh in the current working directory named “mesh_out.su2” by default that is in the SU2 native format. To use it, adjust the MESH_FILENAME and MESH_FORMAT options.

SU2_DEF has other useful capabilities for quickly transforming grids. For example, we often need to scale the grid to be smaller or larger so that the grid is in units of meters. Here, we can take advantage of the SCALE_GRID capability (DV_KIND) while setting a constant scale factor in the DV_VALUE option. In this case, every grid point location will be multiplied by the scaling factor in all dimensions. It is also possible to rigidly rotate or translate the grid with the options ROTATE_GRID and TRANSLATE_GRID, respectively. For example, to scale the grid units by a factor of 10.0, the following options can be used:

% ----------------------- DESIGN VARIABLE PARAMETERS --------------------------%

%

%

% Kind of deformation (NO_DEFORMATION, SCALE_GRID, TRANSLATE_GRID, ROTATE_GRID,

% FFD_SETTING, FFD_NACELLE,

% FFD_CONTROL_POINT, FFD_CAMBER, FFD_THICKNESS, FFD_TWIST

% FFD_CONTROL_POINT_2D, FFD_CAMBER_2D, FFD_THICKNESS_2D,

% FFD_TWIST_2D, HICKS_HENNE, SURFACE_BUMP, SURFACE_FILE)

DV_KIND= SCALE_GRID

%

% - NO_DEFORMATION ( 1.0 )

% - TRANSLATE_GRID ( x_Disp, y_Disp, z_Disp ), as a unit vector

% - ROTATE_GRID ( x_Orig, y_Orig, z_Orig, x_End, y_End, z_End ) axis, DV_VALUE in deg.

% - SCALE_GRID ( 1.0 )

DV_PARAM= ( 1.0 )

%

% Value of the deformation

DV_VALUE= 10.0

Running SU2

The wedge simulation is small and will execute quickly on a single workstation or laptop, and this case will be run in serial. To run this test case, follow these steps at a terminal command line:

- Move to the directory containing the config file (inv_wedge_HLLC.cfg) and the mesh file (mesh_wedge_inv.cgns). Make sure that the SU2 tools were compiled with CGNS support, installed, and that their install location was added to your path.

-

Run the executable by entering

$ SU2_CFD inv_wedge_HLLC.cfgat the command line.

- SU2 will print residual updates with each iteration of the flow solver, and the simulation will finish after reaching the specified convergence criteria.

- Files containing the results will be written upon exiting SU2. The flow solution can be visualized in ParaView (.vtk) or Tecplot (.dat). The output format is specified in the config file.

Results

The following images show some SU2 results for the supersonic wedge problem.

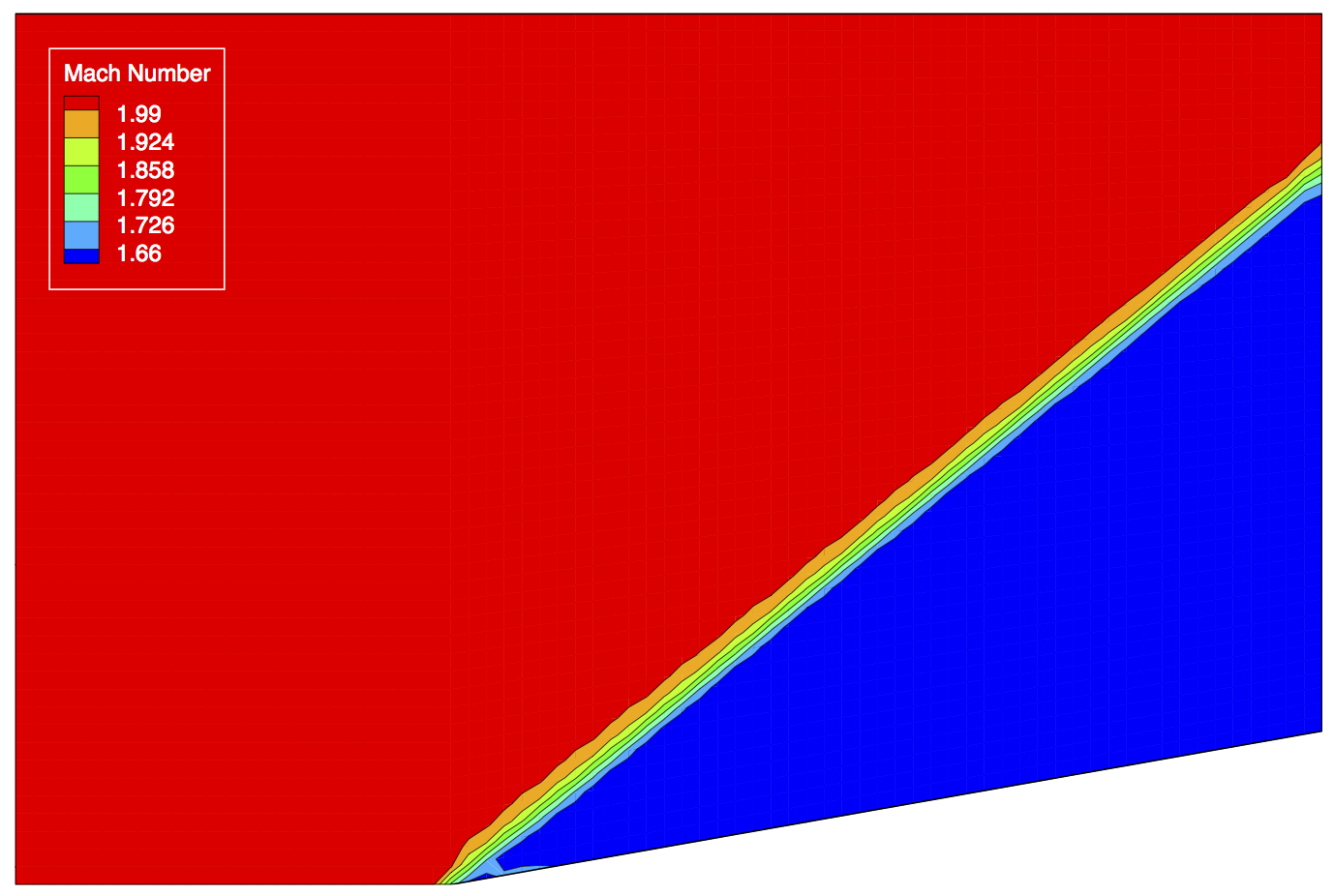

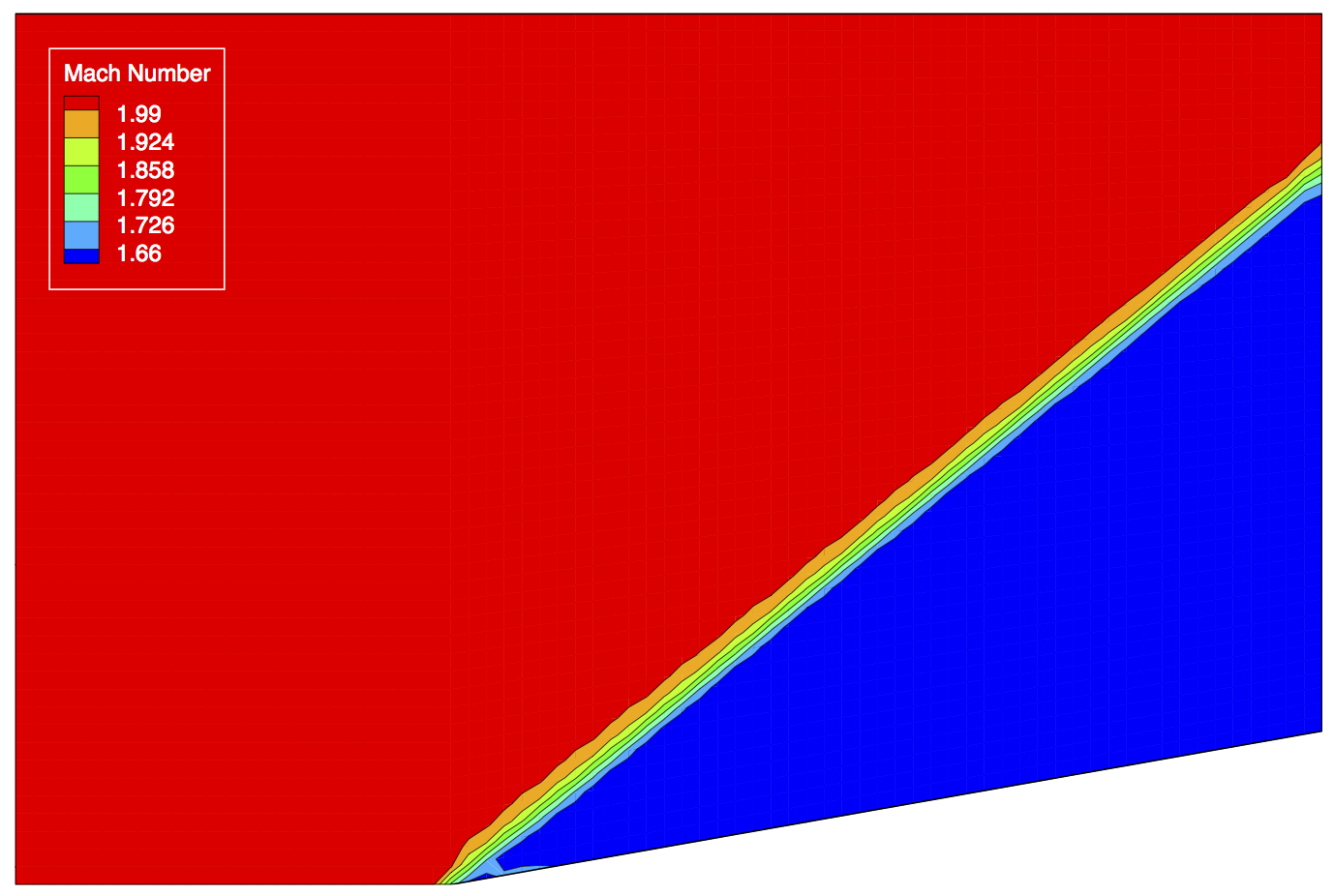

Figure (2): Mach contours showing the oblique shock for supersonic flow over a wedge.

Figure (2): Mach contours showing the oblique shock for supersonic flow over a wedge.

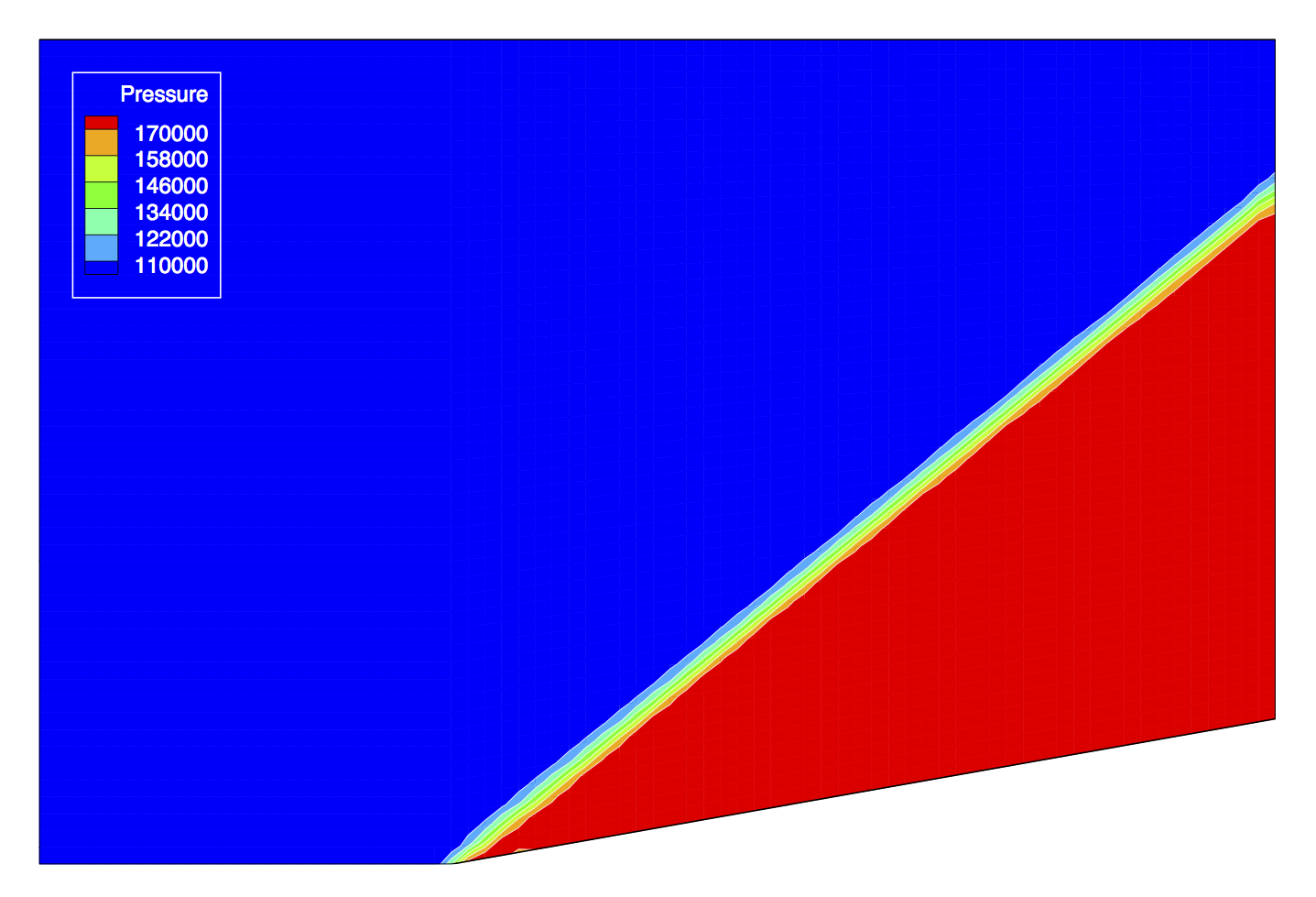

Figure (3): Pressure contours (N/m2) for supersonic flow over a wedge.

Figure (3): Pressure contours (N/m2) for supersonic flow over a wedge.