-

Inviscid Bump in a Channel

Inviscid Supersonic Wedge

Inviscid ONERA M6

Laminar Flat Plate

Laminar Cylinder

Turbulent Flat Plate

Transitional Flat Plate

Transitional Flat Plate for T3A and T3A-

Turbulent ONERA M6

Unsteady NACA0012

Epistemic Uncertainty Quantification of RANS predictions of NACA 0012 airfoil

Non-ideal compressible flow in a supersonic nozzle

Non-ideal compressible flows with physics-informed neural networks

Aachen turbine stage with Mixing-plane

-

Inviscid Hydrofoil

Laminar Flat Plate with Heat Transfer

Turbulent Flat Plate

Turbulent NACA 0012

Laminar Backward-facing Step

Laminar Buoyancy-driven Cavity

Streamwise Periodic Flow

Species Transport

Composition-Dependent model for Species Transport equations

Unsteady von Karman vortex shedding

Turbulent Bend with wall functions

Wind velocity and pollutant dispersion in a city

-

Static Fluid-Structure Interaction (FSI)

Dynamic Fluid-Structure Interaction (FSI) using the Python wrapper and a Nastran structural model

Static Conjugate Heat Transfer (CHT)

Unsteady Conjugate Heat Transfer

Solid-to-Solid Conjugate Heat Transfer with Contact Resistance

Incompressible, Laminar Combustion Simulation

User Defined combustion model with Python

-

Unconstrained shape design of a transonic inviscid airfoil at a cte. AoA

Constrained shape design of a transonic turbulent airfoil at a cte. CL

Constrained shape design of a transonic inviscid wing at a cte. CL

Shape Design With Multiple Objectives and Penalty Functions

Unsteady Shape Optimization NACA0012

Unconstrained shape design of a two way mixing channel

Adjoint design optimization of a turbulent 3D pipe bend

Linear Elasticity

| Written by | for Version | Revised by | Revision date | Revised version |

|---|---|---|---|---|

| @rsanfer | 7.0.2 | @rsanfer | 2020-01-27 | 7.0.2 |

Solver: |

|

Uses: |

|

Prerequisites: |

None |

Complexity: |

Basic |

Goals

As a first approach to the structural solver in SU2, this tutorial will cover the solution of linear elastic problems. This tutorial will guide you through the basic commands for structural analysis, including:

- Setting up an elasticity problem with small deformations

- Linear elastic material model with plane stress formulation

- Non-follower load boundary definition

- Clamped boundary definition

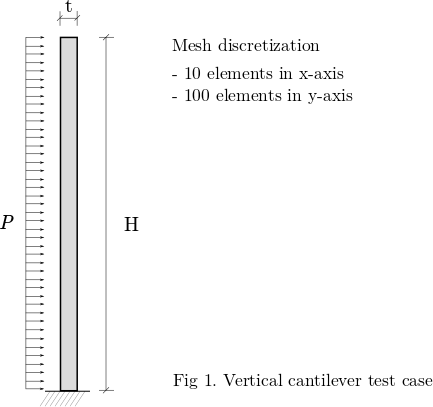

The problem that we will be solving consists of a vertical, slender cantilever, clamped in its base, and subject to a horizontal, distributed load \(P\) on its left boundary. This is shown in Fig. 1.

Resources

First, please make sure you have followed the installation guide and that you have SU2 up and running in your system. You will only need the SU2_CFD binary for this tutorial. If you are building the code from source, a single core version of the code is sufficient for this tutorial.

You can find the resources for this tutorial in the folder structural_mechanics/cantilever in the Tutorials repository. You will need the mesh file mesh_cantilever.su2 and the config file config_linear.cfg.

Background

This tutorial covers the solution of static, solid mechanics problems. The mathematical problem that we will be solving has the well-known form

\[\mathbf{K} \mathbf{u} = \mathbf{F},\]where \(\mathbf{K}\) is the stiffness matrix of the cantilever, \(\mathbf{u}\) is the vector of displacements of the structural nodes and \(\mathbf{F}\) is the vector of applied forces.

This tutorial will be solved the for the cantilever with the following conditions:

- Young’s modulus: \(\mathrm{E = 5.0}\) \(\mathrm{GPa}\)

- Poisson ratio: \(\nu\) \(\mathrm{= 0.35}\)

- Height: \(\mathrm{H = 10}\) \(\mathrm{mm}\)

- Thickness: \(\mathrm{t = 0.5}\) \(\mathrm{mm}\)

Mesh Description

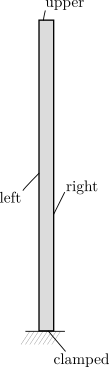

The cantilever is discretized using 1000 4-node quad elements with linear interpolation. The boundaries are defined as follows:

Configuration File Options

We start building the configuration file for SU2 (*.cfg). First of all, we need to determine the solver that we will be using. The keyword for structural problems is ELASTICITY, therefore

SOLVER = ELASTICITY

Structural problems can undergo both geometrical and material non-linearities. In this tutorial, we will be assuming small deformations and linear elastic material behaviour. We set these options using

GEOMETRIC_CONDITIONS = SMALL_DEFORMATIONS

MATERIAL_MODEL = LINEAR_ELASTIC

The structural properties are set through the Young’s modulus, \(\mathrm{E}\), and the Poisson ratio \(\nu\) of the structure, which in this case are set respectively to \(\mathrm{E = 5.0}\) \(\mathrm{GPa}\) and \(\nu\) \(\mathrm{= 0.35}\). As the problem is solved in 2D, a plane stress assumption is imposed,

ELASTICITY_MODULUS = 5.0E9

POISSON_RATIO = 0.35

FORMULATION_ELASTICITY_2D = PLANE_STRESS

The configuration requires to input a mesh file. The mesh that we will be using in this problem is provided for download here, in SU2 format. The options to be added to the config file are

MESH_FORMAT = SU2

MESH_FILENAME = mesh_cantilever.su2

It’s now time to set the boundary conditions of the problem. The load definition is, for this case, \(P(y, t) = P = 1.0 \textrm{kPa}\). To comply with our linear elasticity assumptions, we define \(P\) as a non-follower load, that is, the direction of the load remains constant throughout the simulation, in the x-axis (1, 0). This boundary condition is imposed in the boundary left as

MARKER_LOAD = ( left, 1.0, 1000, 1, 0, 0)

where the 1.0 corresponds to the value of the load, and the 1000 is a multiplier to set the load in kPa. The direction of the load is finally set with the vector (1, 0, 0). Next, the clamped boundary is set as

MARKER_CLAMPED = ( clamped )

Finally, it is required that every other boundary in the problem has a boundary condition imposed. This is because SU2 was originally designed as a Finite-Volume CFD solver, and this imposes some constraints over the boundary description. Therefore, we set the remaining boundaries to have a zero pressure,

MARKER_PRESSURE = ( upper, 0, right, 0)

The equation \(\mathbf{K} \mathbf{u} = \mathbf{F}\) is a linear system, which requires the use of the linear solvers implemented in SU2. There are several options available, and the choice depends on the particular properties of the problem being solved. In this case, we opt for a conjugate gradient solver with ILU preconditioner. The tolerance is set to 1E-8, and the number of iterations is fixed in 1000 to allow for the convergence of the solver.

LINEAR_SOLVER = CONJUGATE_GRADIENT

LINEAR_SOLVER_PREC = ILU

LINEAR_SOLVER_ERROR = 1E-8

LINEAR_SOLVER_ITER = 1000

Finally, the output of the solver needs to be set. We set the screen output to print out the residual of the linear solver in the x and y components of the displacement, and the maximum Von Mises Stress (VMS) in the structure.

In this case, we will write the volume file in Paraview format, as linear_elastic.vtk. The convergence file will be written as history.csv, which in this case will only consists of one line as the linear problem is computed in a single iteration. The binary restart file will be saved as restart_linear_elastic.dat.

SCREEN_OUTPUT = (INNER_ITER, RMS_DISP_X, RMS_DISP_Y, VMS)

TABULAR_FORMAT = CSV

OUTPUT_FILES = (RESTART, PARAVIEW_BINARY)

CONV_FILENAME = history

VOLUME_FILENAME = linear_elastic

RESTART_FILENAME = restart_linear_elastic

Running SU2

This is a very small example that we will run in serial. To run this test case, follow these steps at a terminal command line:

- Move to the directory containing the config file (config_linear.cfg) and the mesh file (mesh_cantilever.su2). Make sure that the SU2 tools were compiled, installed, and that their install location was added to your path.

-

Run the executable by entering

$ SU2_CFD config_linear.cfgat the command line.

- SU2 will print the residual of the linear solver, and the simulation will finish after one iteration.

- Files containing the results will be written upon exiting SU2. The flow solution can be visualized in ParaView (.vtk) or Tecplot (.dat for ASCII).

For this particular problem, the solver should have run very quickly. The screen output of the code will go over your settings, before initializing the solver. Once done so, you will obtain an output such as

+---------------------------------------------------+

| Inner_Iter| rms[DispX]| rms[DispY]| VonMises|

+---------------------------------------------------+

| 0| -9.779193| -9.986436| 1.1541e+06|

where rms[DispX] and rms[DispY] correspond to the residual of the linear solver in the x and y components of the displacements, and VonMises corresponds to the maximum Von Mises Stress in the structural domain.

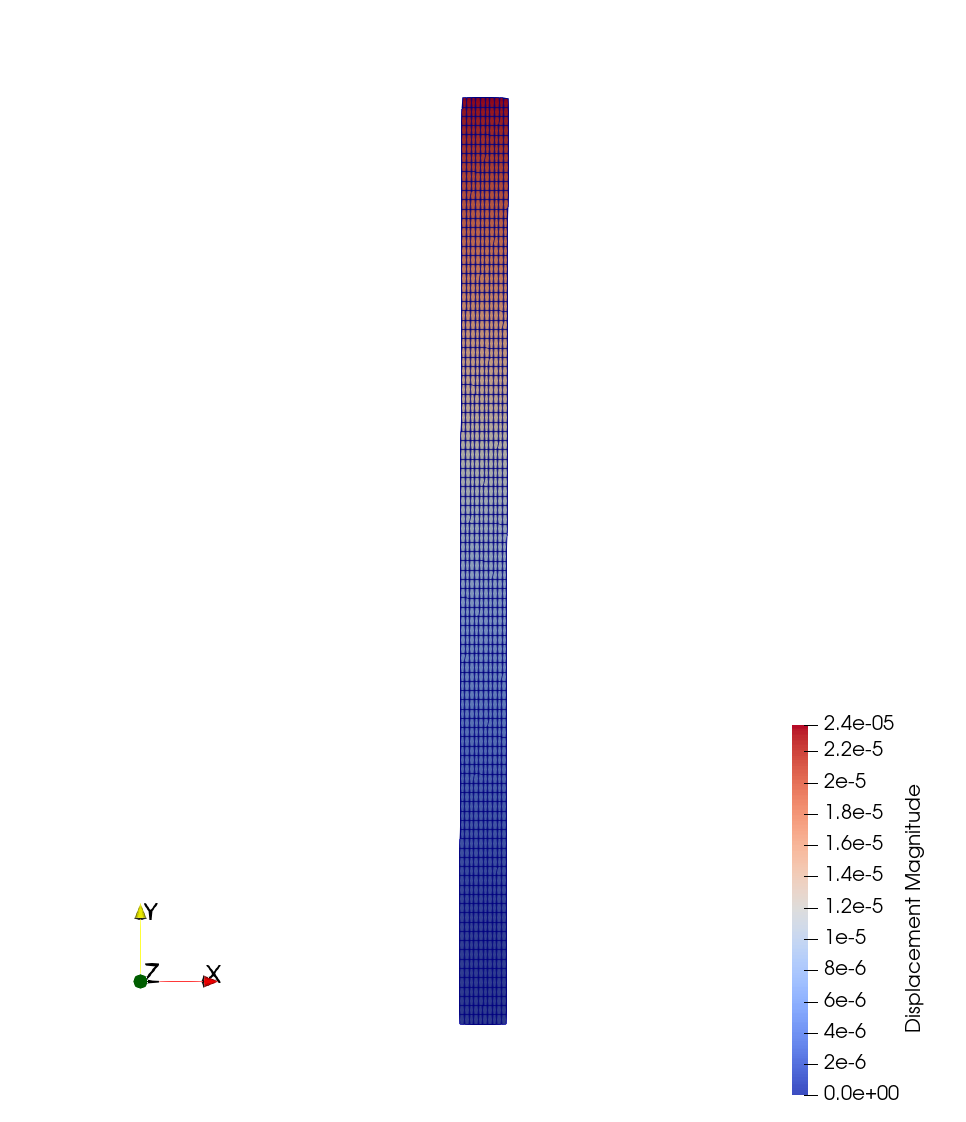

Results

The output file contains the displacement field, the nodal tensions \(\sigma_{xx}\), \(\sigma_{yy}\) and \(\sigma_{xy}\) (as Sxx, Syy and Sxy), and the Von Misses stress. In order to visualize the deformation of the cantilever on Paraview, one can use the filter Warp By Vector applied on the displacement field. The solution of the problem is shown next.

Attribution

If you are using this content for your research, please kindly cite the following reference in your work:

Sanchez, R. et al. (2016), Towards a Fluid-Structure Interaction solver for problems with large deformations within the open-source SU2 suite, 57th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 4-8 January 2016, San Diego, California, USA. DOI: 10.2514/6.2016-0205

-

This work is licensed under a Creative Commons Attribution 4.0 International License