-

Inviscid Bump in a Channel

Inviscid Supersonic Wedge

Inviscid ONERA M6

Laminar Flat Plate

Laminar Cylinder

Turbulent Flat Plate

Transitional Flat Plate

Transitional Flat Plate for T3A and T3A-

Turbulent ONERA M6

Unsteady NACA0012

Epistemic Uncertainty Quantification of RANS predictions of NACA 0012 airfoil

Non-ideal compressible flow in a supersonic nozzle

Non-ideal compressible flows with physics-informed neural networks

Aachen turbine stage with Mixing-plane

-

Inviscid Hydrofoil

Laminar Flat Plate with Heat Transfer

Turbulent Flat Plate

Turbulent NACA 0012

Laminar Backward-facing Step

Laminar Buoyancy-driven Cavity

Streamwise Periodic Flow

Species Transport

Composition-Dependent model for Species Transport equations

Unsteady von Karman vortex shedding

Turbulent Bend with wall functions

Wind velocity and pollutant dispersion in a city

-

Static Fluid-Structure Interaction (FSI)

Dynamic Fluid-Structure Interaction (FSI) using the Python wrapper and a Nastran structural model

Static Conjugate Heat Transfer (CHT)

Unsteady Conjugate Heat Transfer

Solid-to-Solid Conjugate Heat Transfer with Contact Resistance

Incompressible, Laminar Combustion Simulation

User Defined combustion model with Python

-

Unconstrained shape design of a transonic inviscid airfoil at a cte. AoA

Constrained shape design of a transonic turbulent airfoil at a cte. CL

Constrained shape design of a transonic inviscid wing at a cte. CL

Shape Design With Multiple Objectives and Penalty Functions

Unsteady Shape Optimization NACA0012

Unconstrained shape design of a two way mixing channel

Adjoint design optimization of a turbulent 3D pipe bend

Turbulent ONERA M6

| Written by | for Version | Revised by | Revision date | Revised version |

|---|---|---|---|---|

| @economon | 7.0.0 | @talbring | 2020-03-03 | 7.0.2 |

Solver: |

|

Uses: |

|

Prerequisites: |

None |

Complexity: |

Basic |

Goals

Upon completing this tutorial, the user will be familiar with performing a simulation of external, viscous flow around a 3D geometry using a turbulence model. The specific geometry chosen for the tutorial is the classic ONERA M6 wing. Consequently, the following capabilities of SU2 will be showcased in this tutorial:

- Steady, 3D RANS equations

- Spalart-Allmaras turbulence model

- JST convective scheme in space (2nd-order, centered)

- Corrected average-of-gradients viscous scheme

- Euler implicit time integration

- Navier-Stokes Wall, Symmetry, and Far-field boundary conditions

- Code parallelism (optional)

This tutorial also provides an explanation for properly setting up viscous, compressible, 3D flow conditions in SU2. We also introduce a new type of convergence criteria which monitors the change of a specific objective, such as lift or drag, in order to assess convergence.

Resources

The resources for this tutorial can be found in the compressible_flow/Turbulent_ONERAM6 directory in the tutorial repository. You will need the configuration file (turb_ONERAM6.cfg) and the mesh file (mesh_ONERAM6_turb_hexa_43008.su2). It is important to note that the grid used in this tutorial is very coarse to keep computational effort low, and for comparison with literature, finer meshes should be used.

Tutorial

The following tutorial will walk you through the steps required when solving for the flow around the ONERA M6 using SU2. The tutorial will also address procedures for both serial and parallel computations. To this end, it is assumed you have already obtained and compiled SU2_CFD. If you have yet to complete these requirements, please see the Download and Installation pages.

Background

This test case is for the ONERA M6 wing in viscous flow. The ONERA M6 wing was designed in 1972 by the ONERA Aerodynamics Department as an experimental geometry for studying three-dimensional, high Reynolds number flows with some complex flow phenomena (transonic shocks, shock-boundary layer interaction, separated flow). It has become a classic validation case for CFD codes due to the simple geometry, complicated flow physics, and availability of experimental data. This particular study will be performed at a transonic Mach number with the 3D RANS equations in SU2.

Problem Setup

This problem will solve the flow past the wing with these conditions:

- Freestream Temperature = 288.15 K

- Freestream Mach number = 0.8395

- Angle of attack (AOA) = 3.06 deg

- Reynolds number = 11.72E6

- Reynolds length = 0.64607 m

These transonic flow conditions will cause the typical “lambda” shock along the upper surface of the lifting wing.

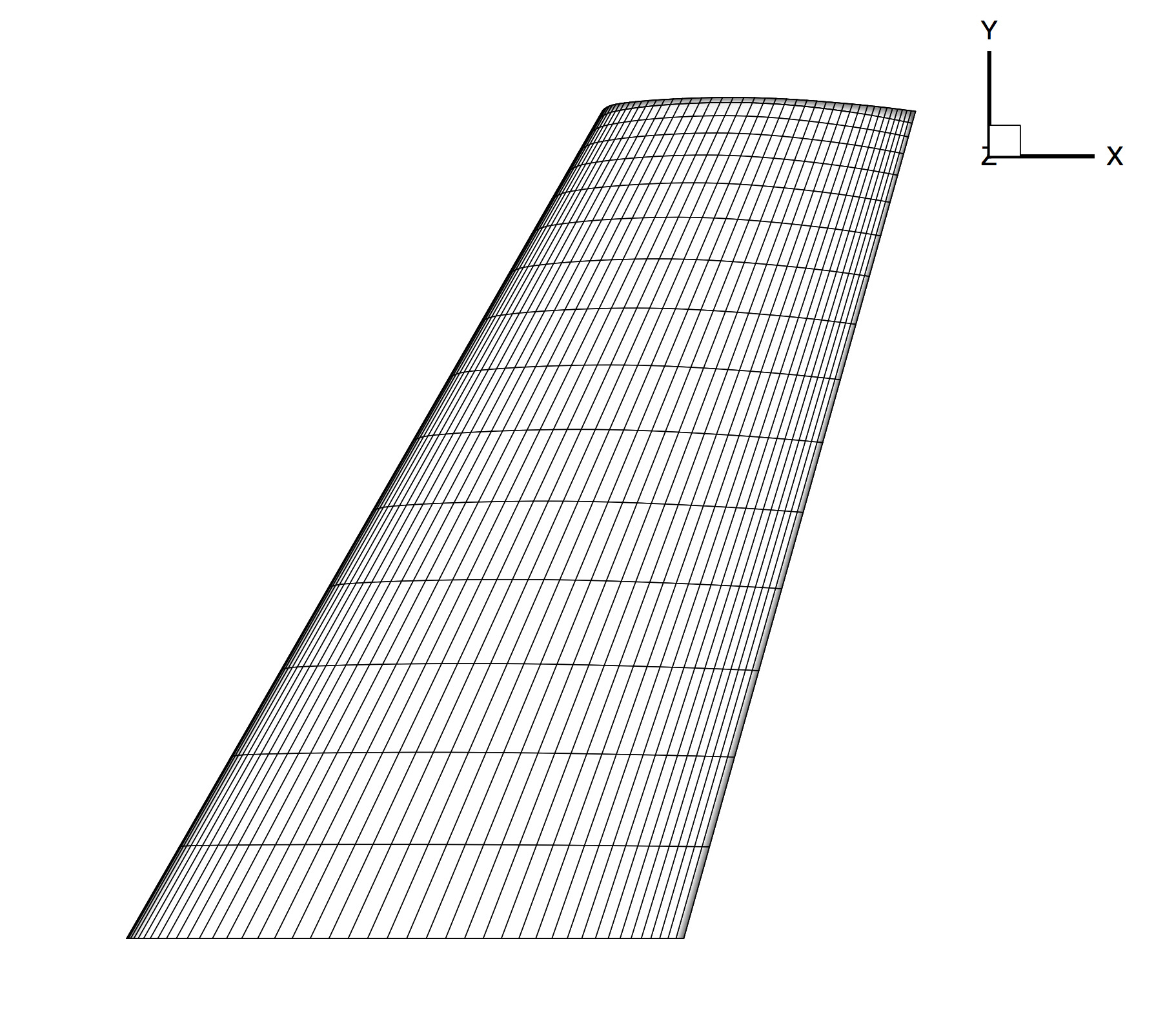

Mesh Description

The computational domain contains the wing half-span mounted on one boundary in the x-z plane. The mesh consists of 43,008 hexahedral elements and 46,417 nodes. Again, we note that this is a very coarse mesh, and should one wish to obtain more accurate solutions for comparison with results in the literature, finer grids should be used.

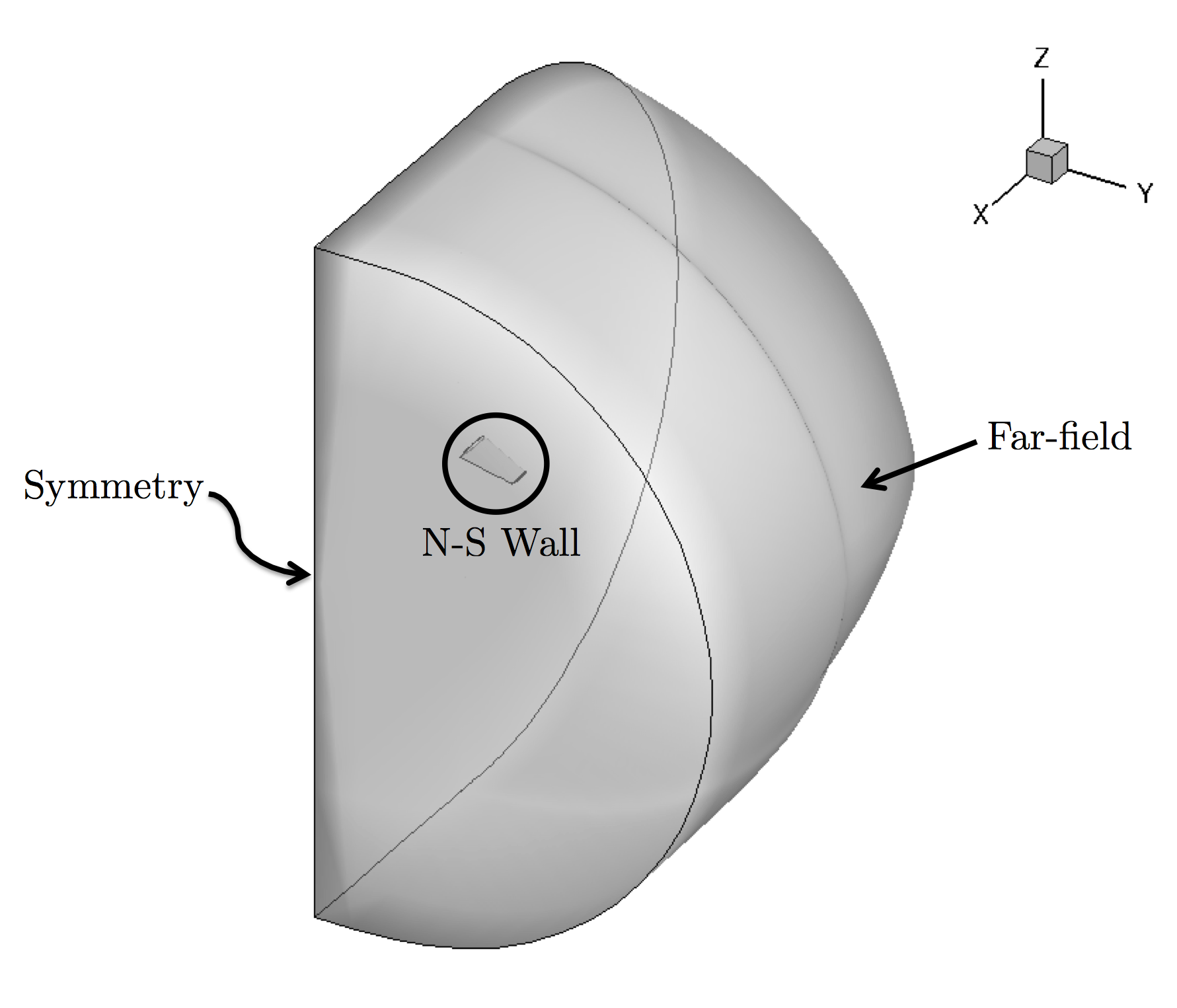

Three boundary conditions are employed: the Navier-Stokes adiabatic wall condition on the wing surface, the far-field characteristic-based condition on the far-field markers, and a symmetry boundary condition for the marker where the wing half-span is attached. The symmetry condition acts to mirror the flow about the x-z plane, reducing the size of the mesh and the computational cost. Images of the entire domain and the quadrilateral elements on the wing surface are shown below.

Figure (1): Far-field view of the computational mesh.

Figure (1): Far-field view of the computational mesh.

Figure (2): Close-up view of the structured surface mesh on the upper wing surface.

Figure (2): Close-up view of the structured surface mesh on the upper wing surface.

Configuration File Options

Several of the key configuration file options for this simulation are highlighted here. We next discuss the proper way to prescribe 3D, viscous, compressible flow conditions in SU2:

% -------------------- COMPRESSIBLE FREE-STREAM DEFINITION --------------------%

%

% Mach number (non-dimensional, based on the free-stream values)

MACH_NUMBER= 0.8395

%

% Angle of attack (degrees, only for compressible flows)

AOA= 3.06

%

% Side-slip angle (degrees, only for compressible flows)

SIDESLIP_ANGLE= 0.0

%

% Init option to choose between Reynolds (default) or thermodynamics quantities

% for initializing the solution (REYNOLDS, TD_CONDITIONS)

INIT_OPTION= REYNOLDS

%

% Free-stream option to choose between density and temperature (default) for

% initializing the solution (TEMPERATURE_FS, DENSITY_FS)

FREESTREAM_OPTION= TEMPERATURE_FS

%

% Free-stream temperature (288.15 K by default)

FREESTREAM_TEMPERATURE= 288.15

%

% Reynolds number (non-dimensional, based on the free-stream values)

REYNOLDS_NUMBER= 11.72E6

%

% Reynolds length (1 m by default)

REYNOLDS_LENGTH= 0.64607

The options above set the conditions for a 3D, viscous flow. The MACH_NUMBER, AOA, and SIDESLIP_ANGLE options remain the same as they appeared for the inviscid ONERA M6 tutorial, which includes a description of the freestream flow direction.

For this problem, SU2 is using a calorically perfect gas model which is selected by setting the FLUID_MODEL to STANDARD_AIR. The fluid flow properties can be changed by selecting a different fluid model. In addition, the models for the transport coefficients can also be customized by exploring the viscosity and thermal conductivity options. By default with compressible flow, the laminar viscosity is governed by Sutherland’s law, and the thermal conductivity is assumed to depend on a constant Prandtl number.

% ---- IDEAL GAS, POLYTROPIC, VAN DER WAALS AND PENG ROBINSON CONSTANTS -------%

%

% Different gas model (STANDARD_AIR, IDEAL_GAS, VW_GAS, PR_GAS)

FLUID_MODEL= STANDARD_AIR

%

% Ratio of specific heats (1.4 default and the value is hardcoded

% for the model STANDARD_AIR)

GAMMA_VALUE= 1.4

%

% Specific gas constant (287.058 J/kg*K default and this value is hardcoded

% for the model STANDARD_AIR)

GAS_CONSTANT= 287.058

% --------------------------- VISCOSITY MODEL ---------------------------------%

%

% Viscosity model (SUTHERLAND, CONSTANT_VISCOSITY).

VISCOSITY_MODEL= SUTHERLAND

%

% Sutherland Viscosity Ref (1.716E-5 default value for AIR SI)

MU_REF= 1.716E-5

%

% Sutherland Temperature Ref (273.15 K default value for AIR SI)

MU_T_REF= 273.15

%

% Sutherland constant (110.4 default value for AIR SI)

SUTHERLAND_CONSTANT= 110.4

% --------------------------- THERMAL CONDUCTIVITY MODEL ----------------------%

%

% Conductivity model (CONSTANT_CONDUCTIVITY, CONSTANT_PRANDTL).

CONDUCTIVITY_MODEL= CONSTANT_PRANDTL

%

% Laminar Prandtl number (0.72 (air), only for CONSTANT_PRANDTL)

PRANDTL_LAM= 0.72

%

% Turbulent Prandtl number (0.9 (air), only for CONSTANT_PRANDTL)

PRANDTL_TURB= 0.90

Initialization of the flow field for compressible problems can be performed by multiple methods. The default method is to intitialize using the specified Reynolds number (INIT_OPTION= REYNOLDS) and free-stream temperature (FREESTREAM_OPTION= TEMPERATURE_FS), which will be used in this case. It is also possible to initialize the flow from thermodynamic quantities directly with INIT_OPTION= TD_CONDITIONS, in which case, the Reynolds number option will be ignored. Regardless of initialization method, we recommend that you always confirm the resulting initialization state in the console output during runtime of SU2 that is reported just before the solver begins iterating.

For a viscous simulation, the numerical experiment must match the physical reality. This flow similarity is achieved by matching the REYNOLDS_NUMBER and REYNOLDS_LENGTH to the original system (assuming the Mach number and the geometry already match). Upon starting a viscous simulation in SU2, the following steps are performed to set the flow conditions internally when INIT_OPTION= REYNOLDS and FREESTREAM_OPTION= TEMPERATURE_FS:

- Use the gas constants and freestream temperature to calculate the speed of sound.

- Calculate the freestream velocity vector from the Mach number,

AOA/SIDESLIP_ANGLE, and speed of sound from step 1. - Compute the freestream viscosity by using the viscosity model specified in the config file.

- Use the definition of the Reynolds number to find the freestream density from the supplied Reynolds information, freestream velocity, and freestream viscosity from step 3.

- Calculate the freestream pressure using the perfect gas law with the freestream temperature, specific gas constant, and freestream density from step 4. Note that the freestream pressure supplied in the configuration file will be ignored with this method of initialization.

This method for setting similar flow conditions assumes that all inputs are in SI units, including the mesh geometry, which should be in meters. As described in the inviscid wedge tutorial, you can easily scale your mesh file to the appropriate size with the SU2_DEF module.

Lastly, SU2 features multiple ways to assess convergence:

% Convergence criteria

CONV_FIELD= DRAG

%

% Start convergence criteria at iteration number

CONV_STARTITER= 10

%

% Number of elements to apply the criteria

CONV_CAUCHY_ELEMS= 100

%

% Epsilon to control the series convergence

CONV_CAUCHY_EPS= 1E-6

Rather than achieving a certain order of magnitude reduction in a residual to judge convergence, convergence of the drag coefficient is chosen for this problem. When a coefficient such as drag is chosen, we measure the change in the specific quantity of interest over a specified number of previous iterations. With the options selected above, the calculation will terminate when the change in the drag coefficient for the wing over the previous 100 iterations (CONV_CAUCHY_ELEMS) becomes less than 1E-6 (CONV_CAUCHY_EPS). A convergence criteria of this nature can be very useful for design problems where the solver is embedded in a larger design loop and reliable convergence behavior is essential.

Running SU2

Instructions for running this test case are given here for both serial and parallel computations.

In Serial

The wing mesh should fit on a single-core machine. To run this test case in serial, follow these steps at a terminal command line:

- Move to the directory containing the config file (turb_ONERAM6.cfg) and the mesh file (mesh_ONERAM6_turb_hexa_43008.su2). Make sure that the SU2 tools were compiled, installed, and that their install location was added to your path.

-

Run the executable by entering in the command line:

$ SU2_CFD turb_ONERAM6.cfg - SU2 will print residual updates with each iteration of the flow solver, and the simulation will terminate after reaching the specified convergence criteria.

- Files containing the results will be written upon exiting SU2. The flow solution can be visualized in ParaView (.vtk) or Tecplot (.dat for ASCII).

In Parallel

If SU2 has been built with parallel support, the recommended method for running a parallel simulation is through the use of the parallel_computation.py Python script. This automatically handles the domain decomposition and execution with SU2_CFD, and the merging of the decomposed files using SU2_SOL. Follow these steps to run the ONERA M6 case in parallel:

- Move to the directory containing the config file (turb_ONERAM6.cfg) and the mesh file (mesh_ONERAM6_turb_hexa_43008.su2). Make sure that the SU2 tools were compiled with parallel support, installed, and that their install location was added to your path.

-

Run the python script which will automatically call SU2_CFD and will perform the simulation using

NPnumber of processors by entering in the command line:$ parallel_computation.py -n NP -f turb_ONERAM6.cfg - SU2 will print residual updates with each iteration of the flow solver, and the simulation will terminate after reaching the specified convergence criteria.

- The python script will automatically call the

SU2_SOLexecutable for generating visualization files from the native restart file written during runtime. The flow solution can then be visualized in ParaView (.vtk) or Tecplot (.dat for ASCII).

Results

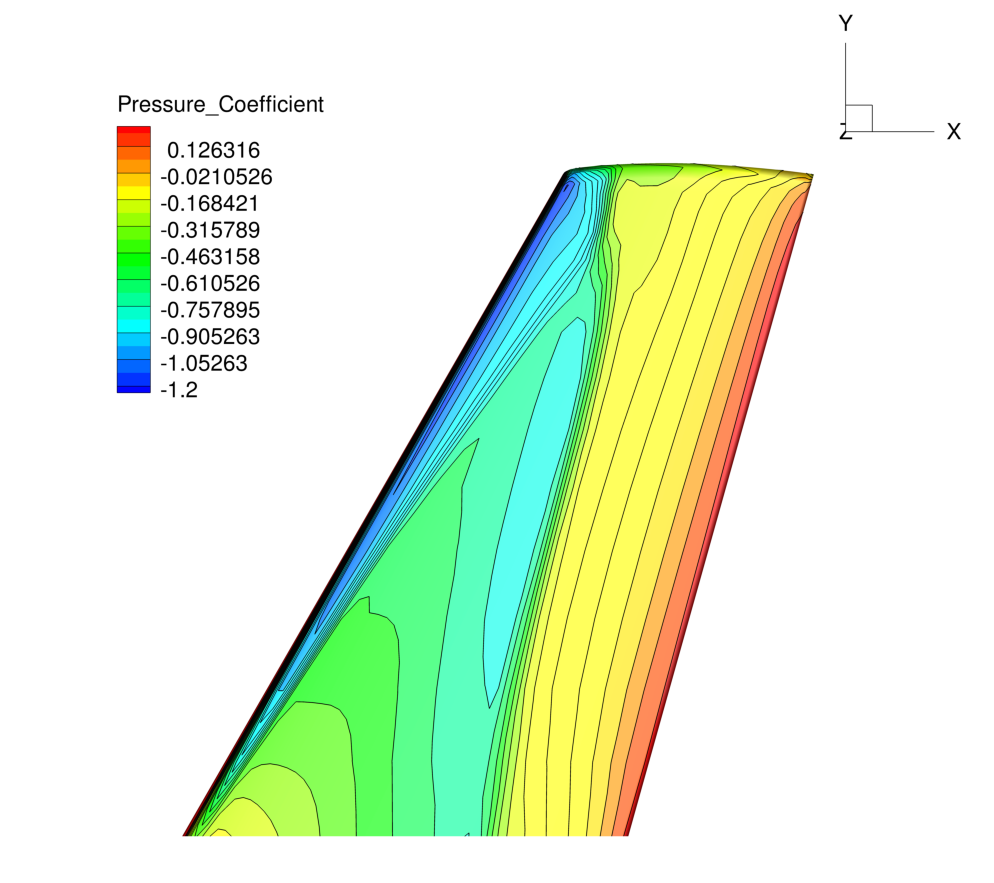

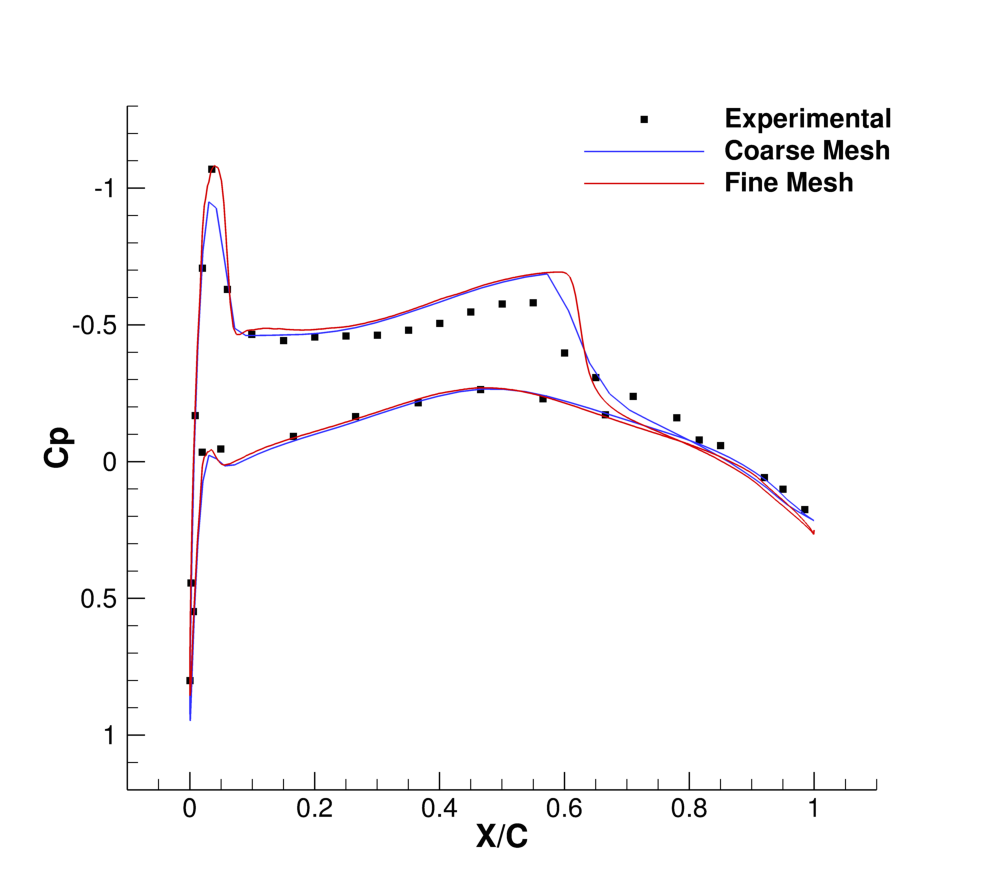

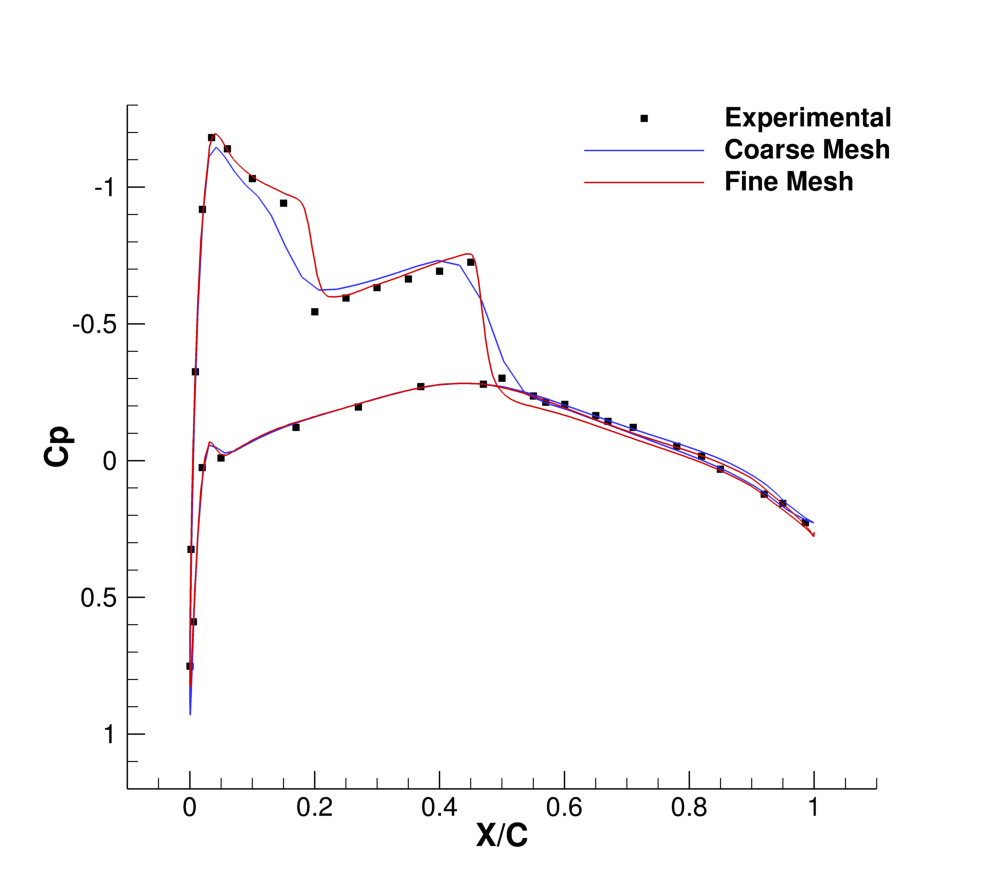

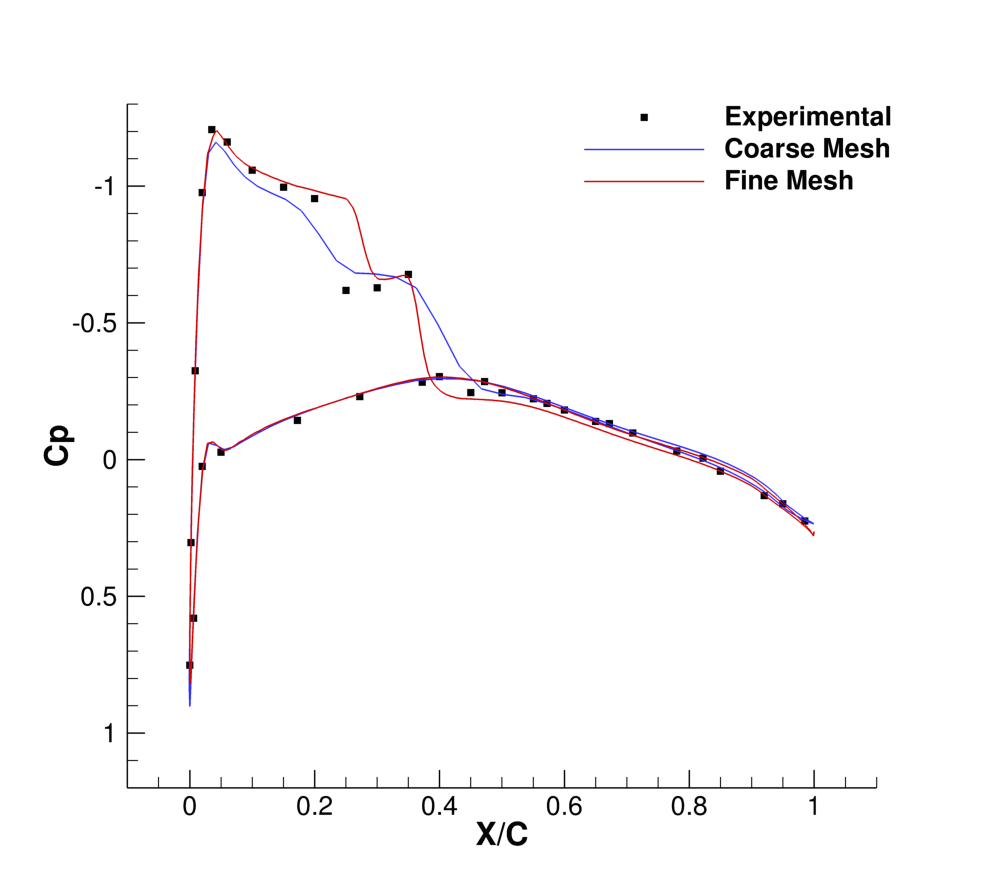

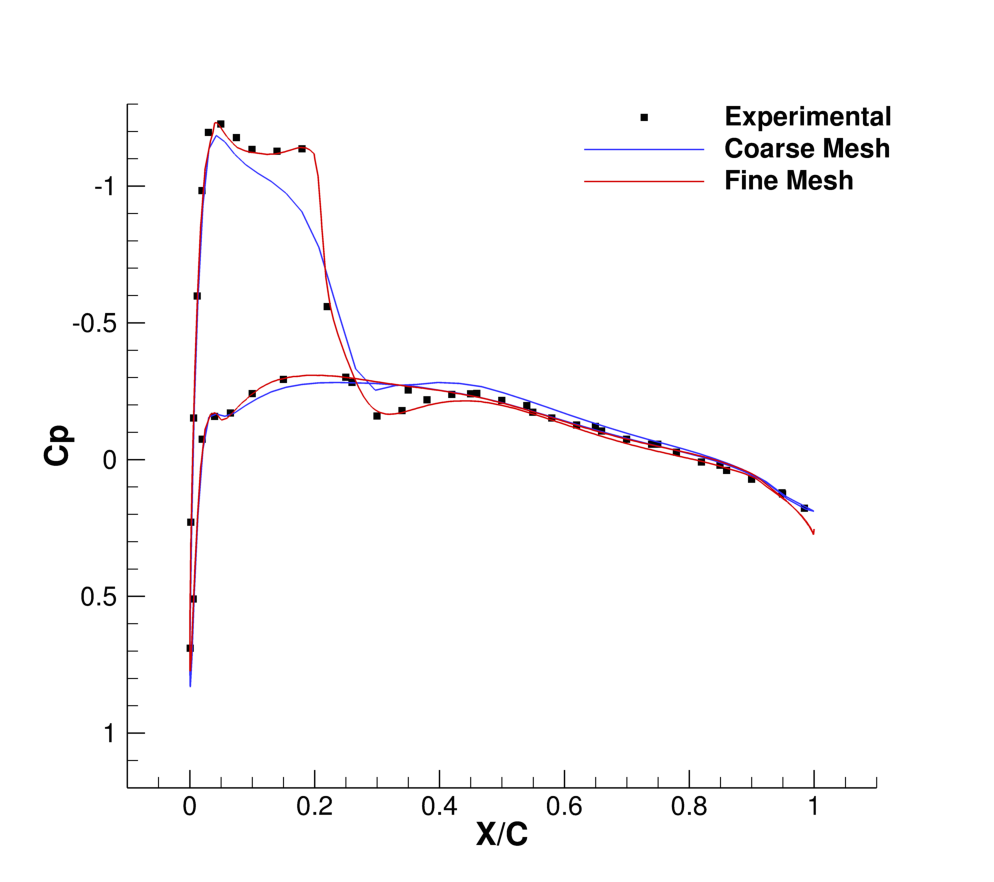

Results for the turbulent flow over the ONERA M6 wing are shown below. As part of this tutorial a coarse mesh has been provided, but for comparison the results obtained by using a refined mesh (9,252,922 nodes) as well as experimental results are shown.

Figure (3): Comparison of Cp profiles of the experimental results of Schmitt and Carpin (red squares) against SU2 computational results (blue line) at different sections along the span of the wing. (a) y/b = 0.2, (b) y/b = 0.65, (c) y/b = 0.8, (d) y/b = 0.95.